AGITATOR AGITATOR

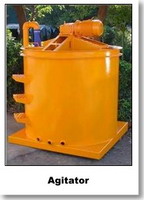

The

function of the Agitator is to prevent the slurry mixture from setting

while in storage. This is achieved by a rotating mechanism - consisted

of an electric motor with reduction gear rotating a shaft fitted with

three blades at the base of the Agitator tank. The rotating blades keep

the slurry ¡§agitated¡¨.

In an automatic cycle mode, the level of slurry in the Agitator tank is

controlled by a level sensor installed near to the top of the tank.

This prevent overflowing and also the keep the tank full at all time

throughout the cycle.

PNEUMATIC SYSTEM

This consists of a air compressor and an electro-pneumatic control

system that controls and operates the pneumatic valves for the water,

cement feeding and the mixing process.

ELECTRICAL POWER SUPPLY AND CONTROL BOARD

The board contains all the electrical equipment needed to power

the various motors as well as the auxiliary equipment, including the

load cell measurement box, and the programmable controller that handles

operation of the automatic cycle.

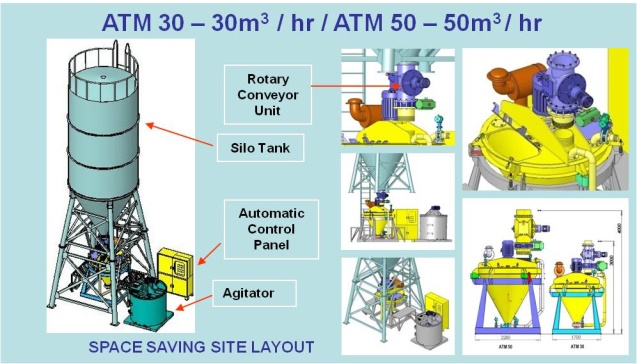

AUTOMATIC TURBO MIXER - ATM 30

|

| SPECIFICATION |

UNITS

|

|

| MODEL |

|

ATM

30

|

|

TURBO MIXER

|

|

|

|

OUTER DIAMETER

|

mm

|

1500

|

|

HEIGHT

|

mm

|

1250

|

|

VOLUME

|

Liter

|

700

|

|

BATCH CAPACITY

|

Liter

|

500

|

|

ELECTRIC MOTOR

|

HP

|

20hp /

4P/1460/1760rpm

|

| AUTOMATIC

PNEUMATIC CONTROL VALVES |

sets |

1 |

|

ROTARY CONVEYOR

|

no.

|

1

|

|

ELECTRONIC LOAD CELLS

|

no.

|

3

|

|

BREAHTER FILTER 6"

|

no.

|

1

|

|

GROSS WEIGHT

|

kg

|

1500

|

|

ELECTRICAL SOURCE

|

|

220V~440V /

50 / 60Hz

|

|

PATENT NO. 064011

|

|

|

|

AUTOMATIC TURBO

MIXER - ATM 50

|

|

SPECIFICATION

|

UNITS

|

|

|

MODEL

|

|

ATM

50

|

|

TURBO

MIXER

|

|

|

|

TANK

VOLUME

|

Liter

|

2600

|

|

BATCH

CAPACITY

|

Liter

|

1500

|

|

ELECTRIC

MOTOR

|

HP

|

40hp /

4P/1460/1760rpm

|

ELECTRO

- PNEUMATIC CONTROL WITH PLC SYSTEM

|

sets |

1 |

|

ROTARY

CONVEYOR

|

no.

|

1

|

|

LOAD

CELLS

|

no.

|

3

|

|

BREAHTER

FILTER 6"

|

no.

|

1

|

|

GROSS

WEIGHT

|

kg

|

2600

|

|

ELECTRICAL

SOURCE

|

|

220V~440V /

50 / 60Hz

|

|

PATENT

NO. 064011

|

|

|

|

|

|